1

/

of

27

Luoyang Shike Industrial Technology Co., Ltd.

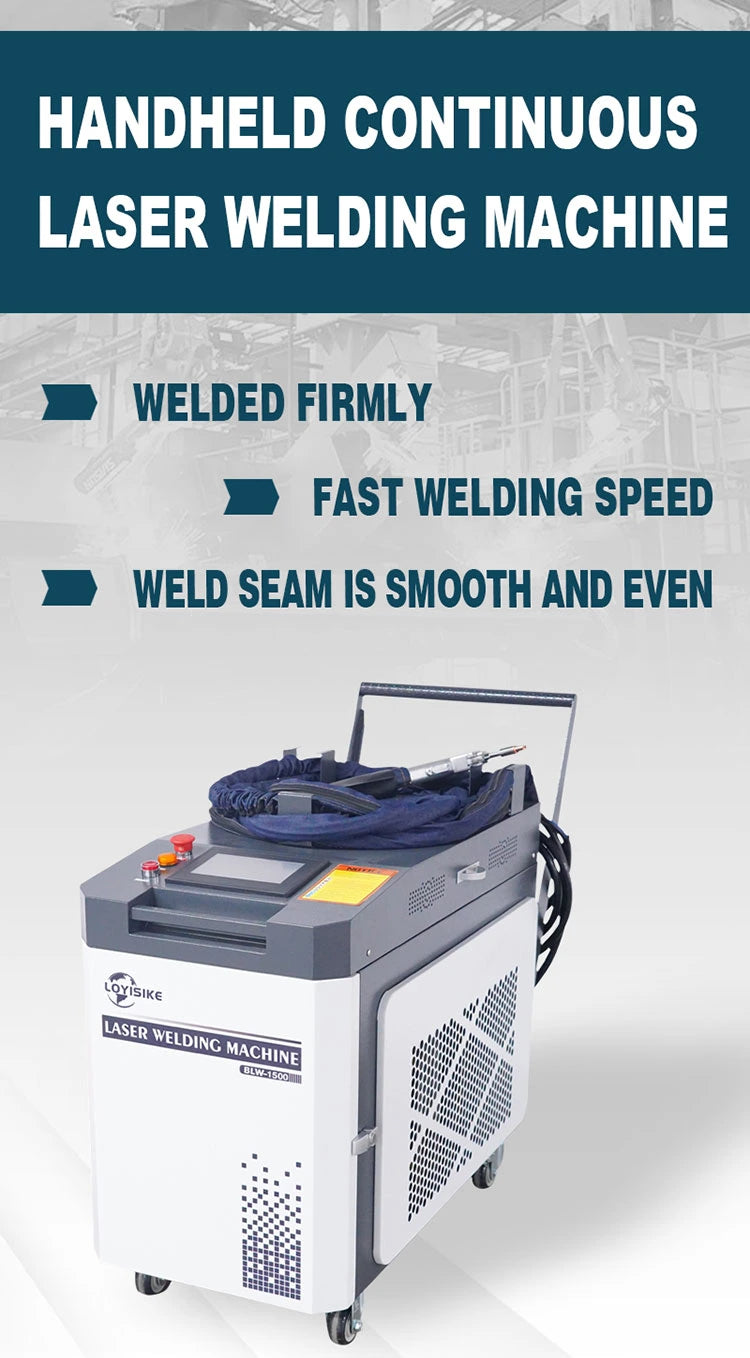

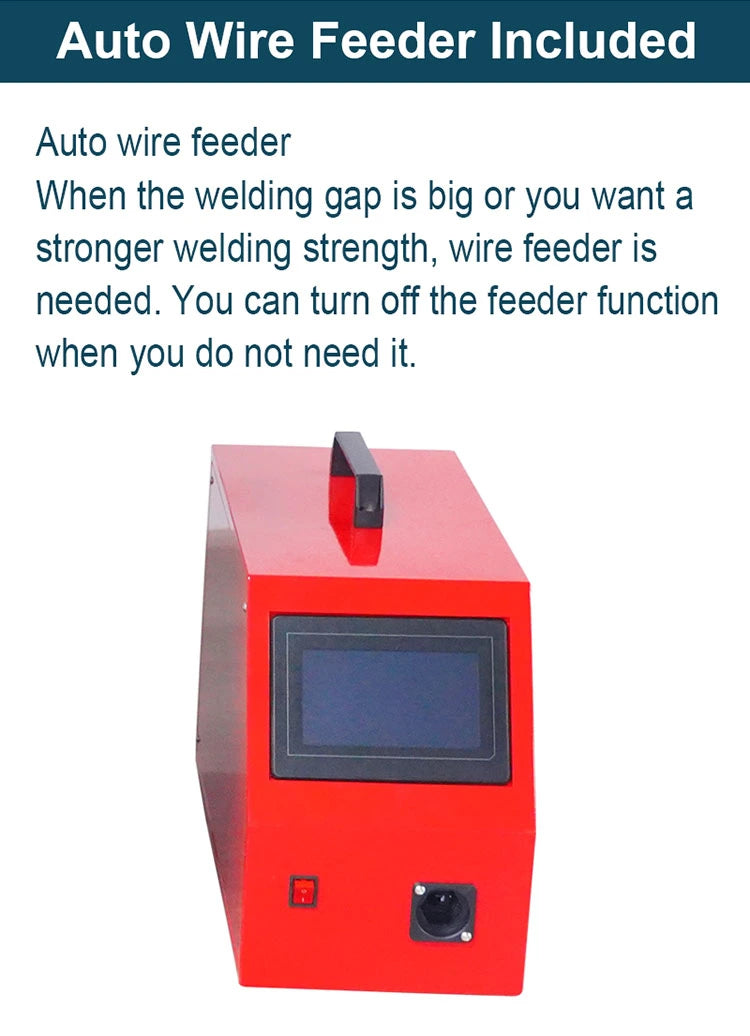

2000W Handheld Fiber Laser Welding Machine MAX Laser Source Laser Welder with Auto Wire Feeder

2000W Handheld Fiber Laser Welding Machine MAX Laser Source Laser Welder with Auto Wire Feeder

Regular price

$11,099.00

Regular price

Sale price

$11,099.00

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

2000W Handheld Fiber Laser Welding Machine MAX Laser Source Laser Welder with Auto Wire Feeder

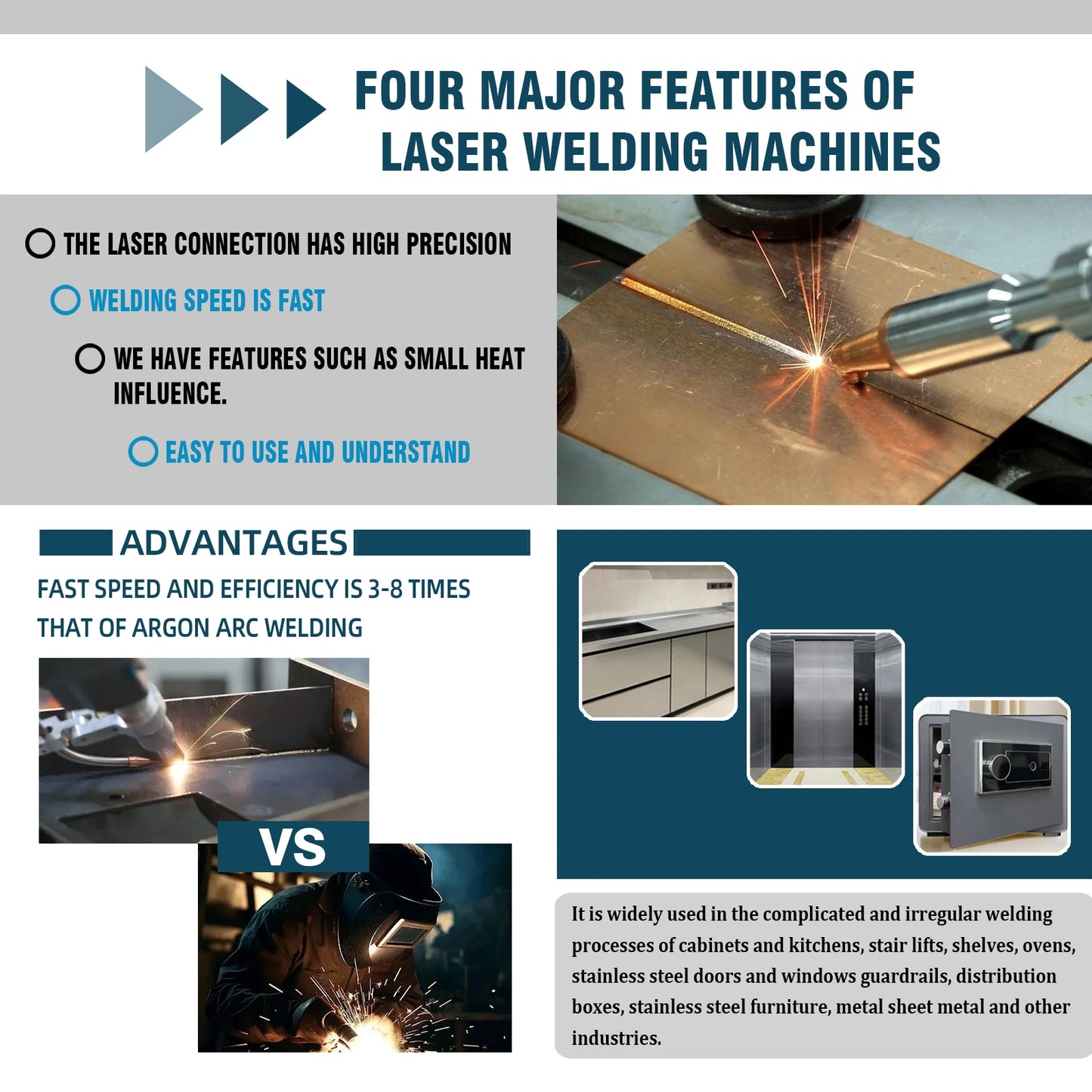

Key Advantages of LOYISIKE Laser Welding Machine

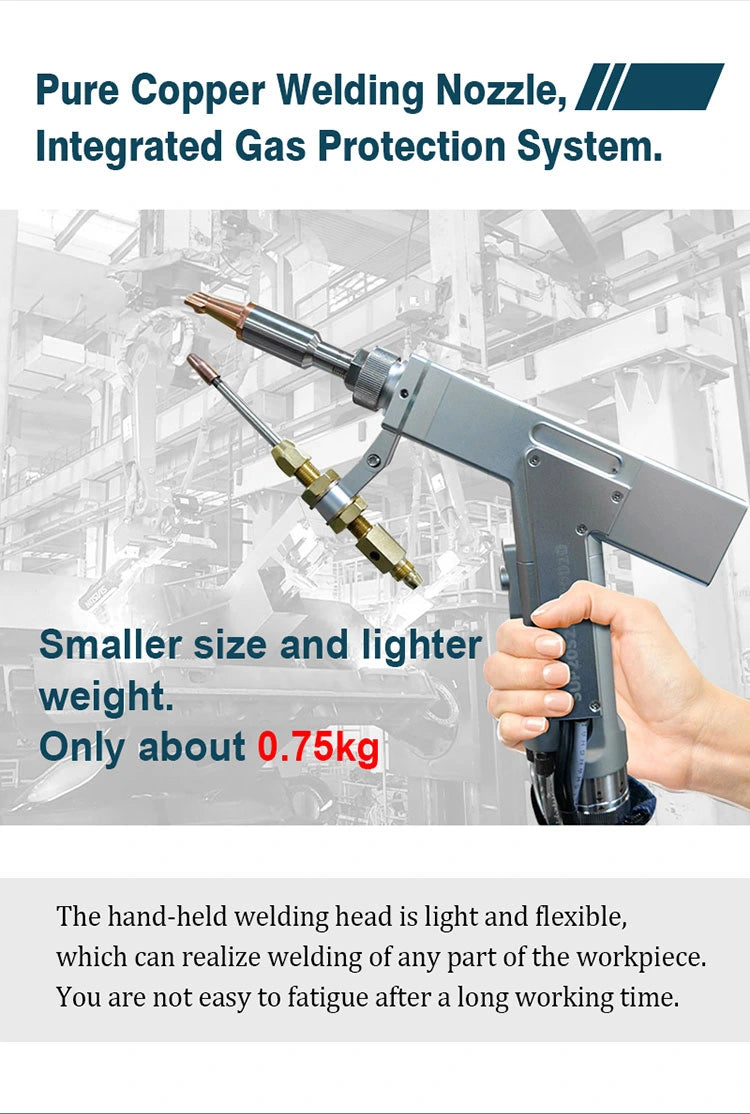

- The handheld welding head is remarkably lightweight and flexible, weighing only about 0.75kg. It enables easy access to weld any part of a workpiece and significantly reduces operator fatigue even during prolonged use.

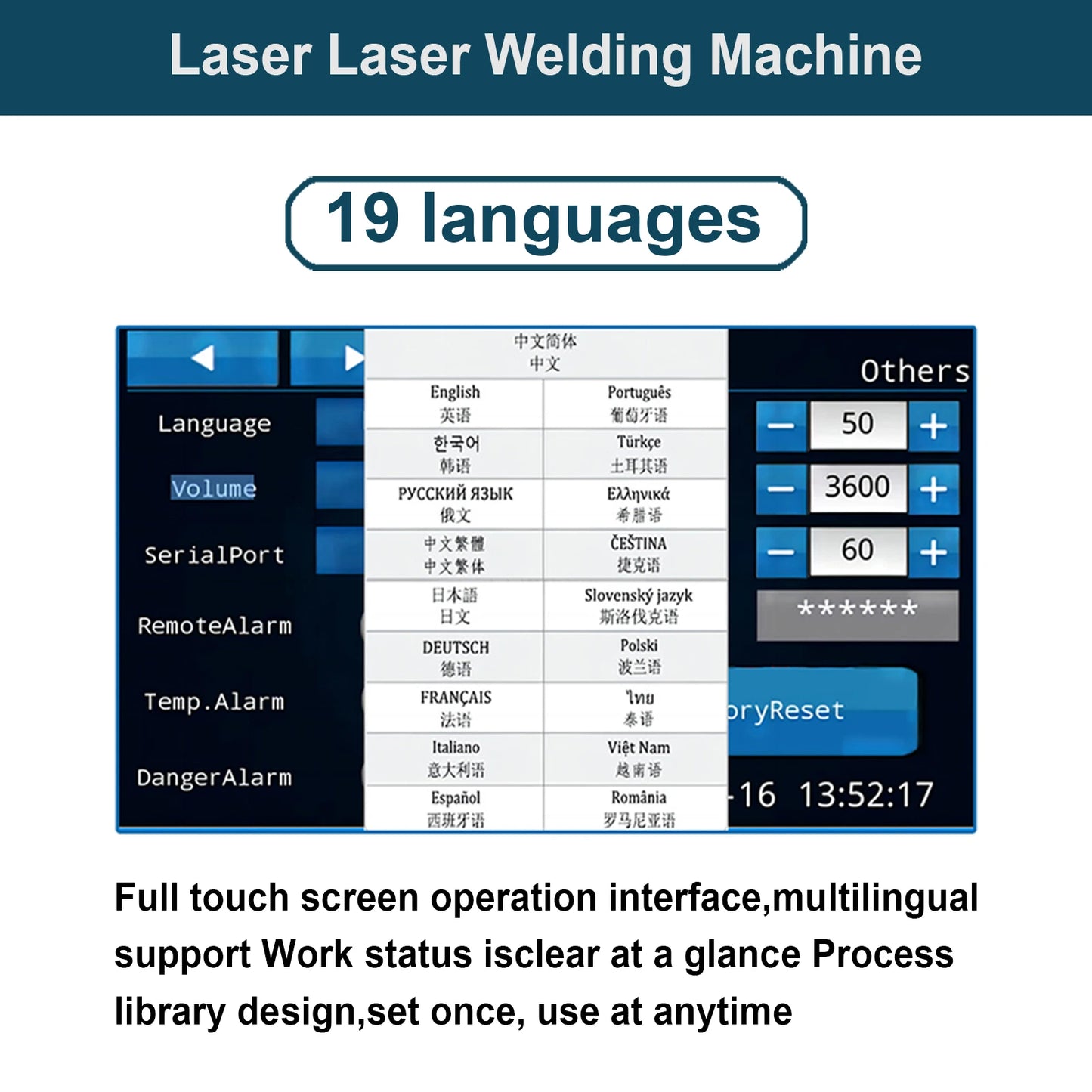

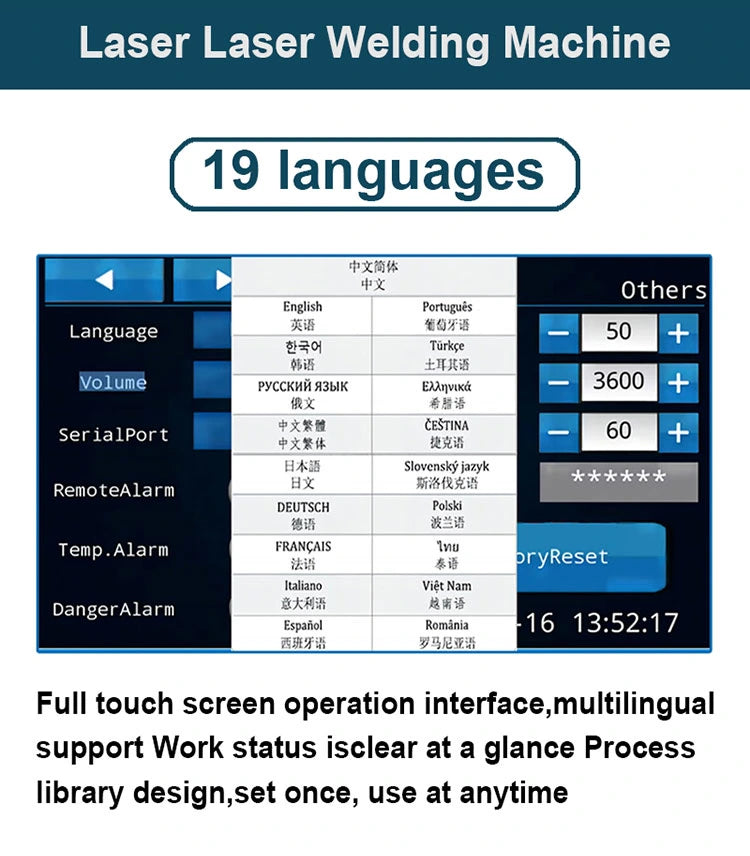

- The full touchscreen interface, with multi-language support, ensures intuitive operation and clear visibility of working status. The process library feature allows users to save settings once and reuse them anytime, improving consistency and convenience.

- High Energy Density: The laser beam can be focused onto a very small area, generating extremely high power density and achieving deep fusion welding.

- Non-Contact Processing: Processing is stress-free, preventing tool wear and workpiece surface damage.

- Precise Control: Easily integrated with precision machine tools and robots, enabling automated welding of complex paths.

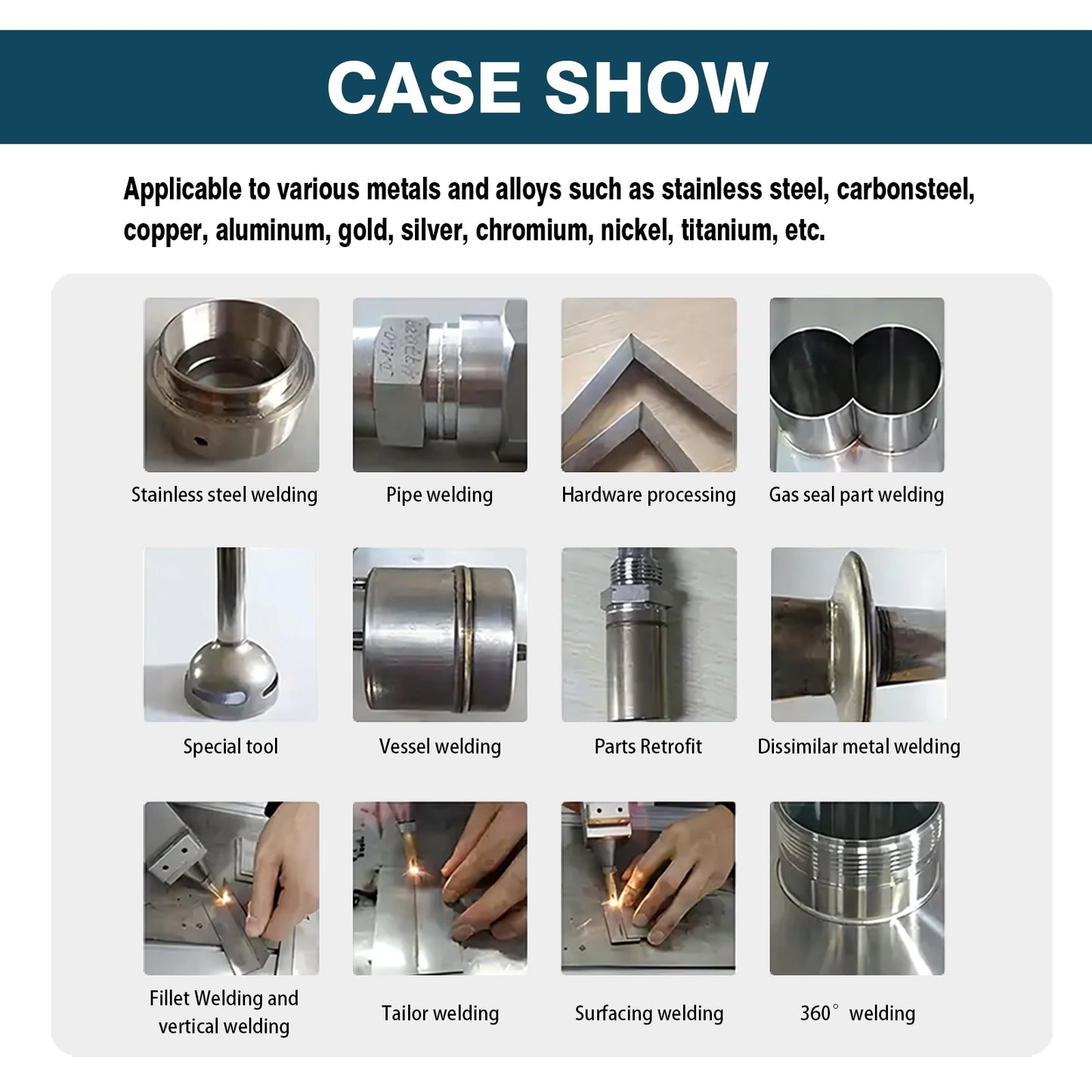

- High Flexibility: A wide range of materials can be welded, including various metals and dissimilar non-metallic materials.

- Quality Advantages: Welds offer a large depth-to-width ratio, aesthetically pleasing and smooth welds, high strength, no contamination, minimal heat-affected zones, and minimal workpiece deformation.

- Efficiency Advantages: High welding speeds, no electrodes or filler materials, and minimal downtime, significantly improving production efficiency.

- Cost Advantages: Low energy consumption over long-term operation, no consumables, relatively low maintenance costs, and high overall efficiency.

- Operational Advantages: Welding can be performed through transparent media such as glass, making it easy to integrate into automated production lines and enabling remote operation.

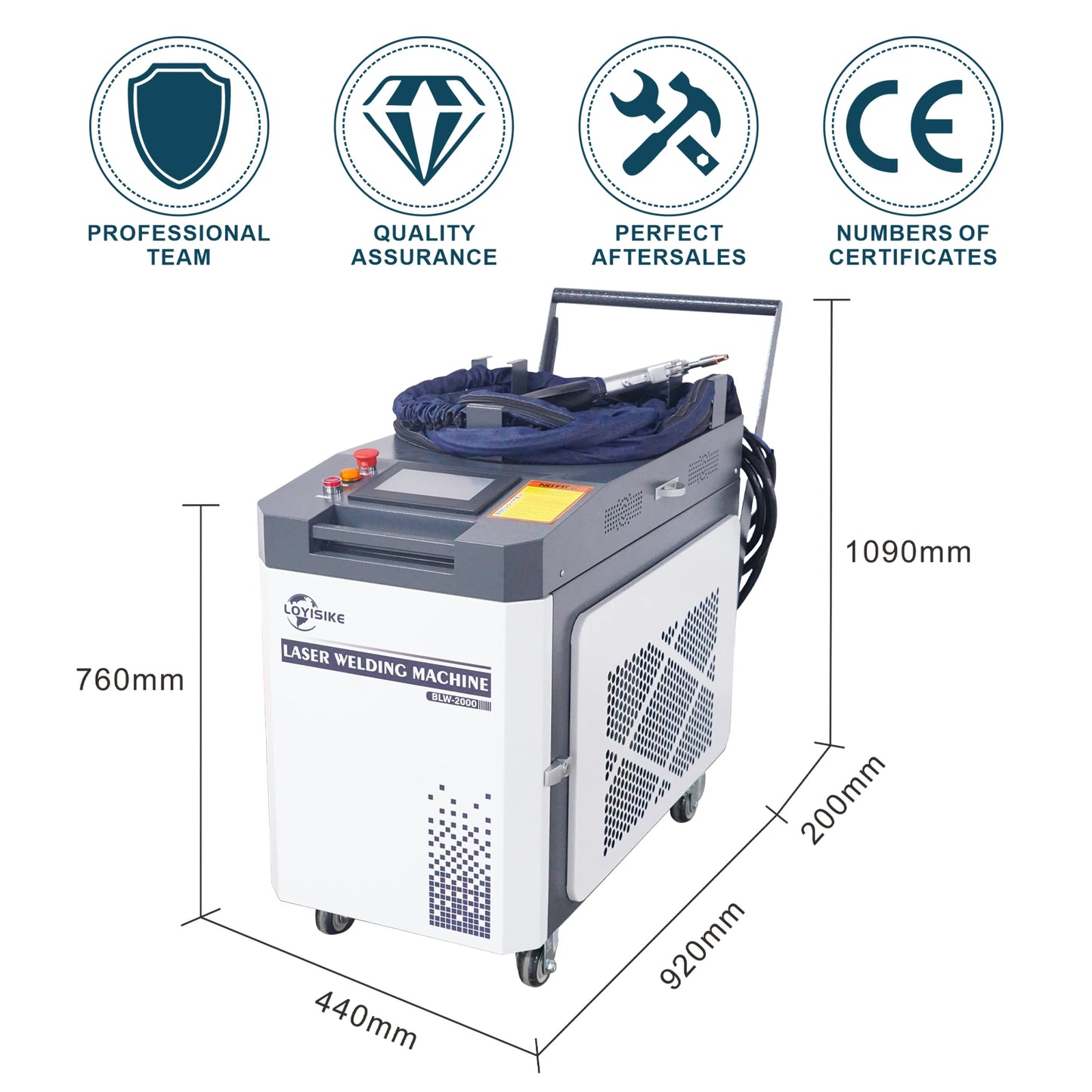

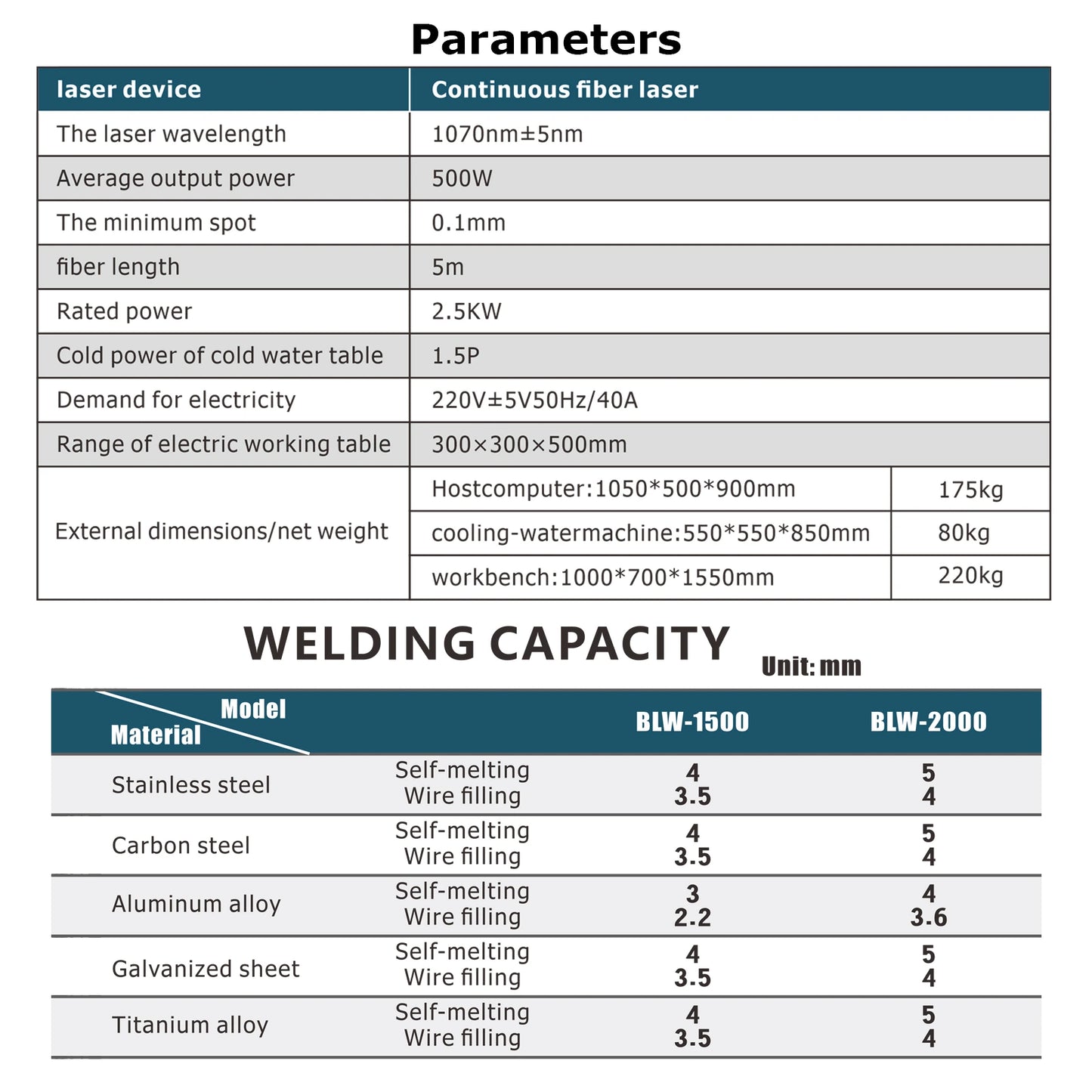

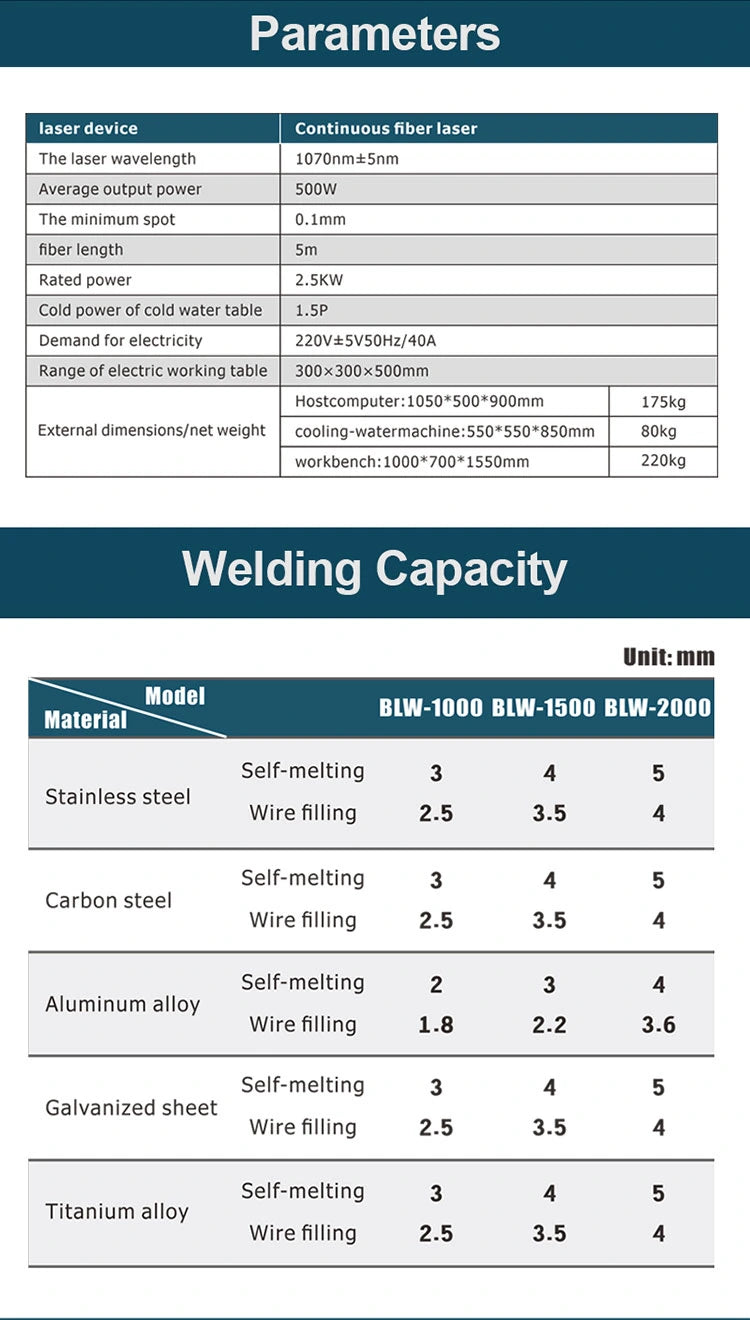

Technical Parameters of Laser Welding Machine

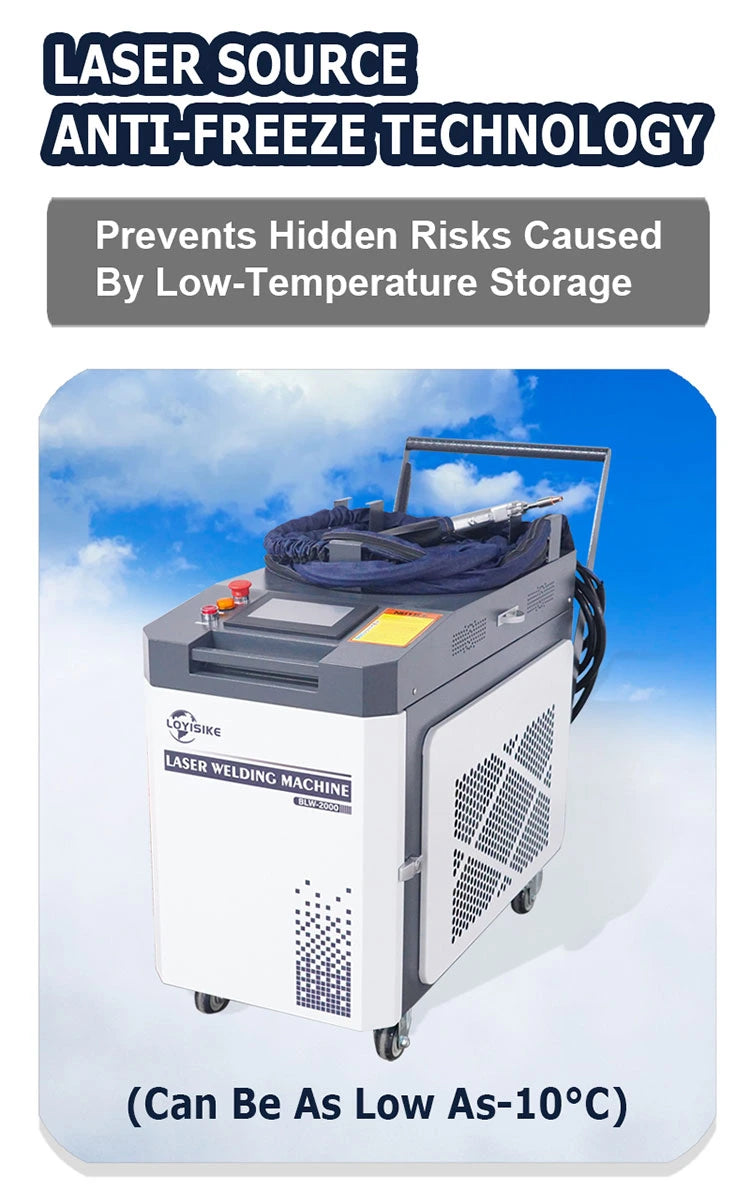

- Power: 2000W

- Laser Model: Continuous Fiber Laser

- Average Output Power:500W

- Rated Power:2.5kW

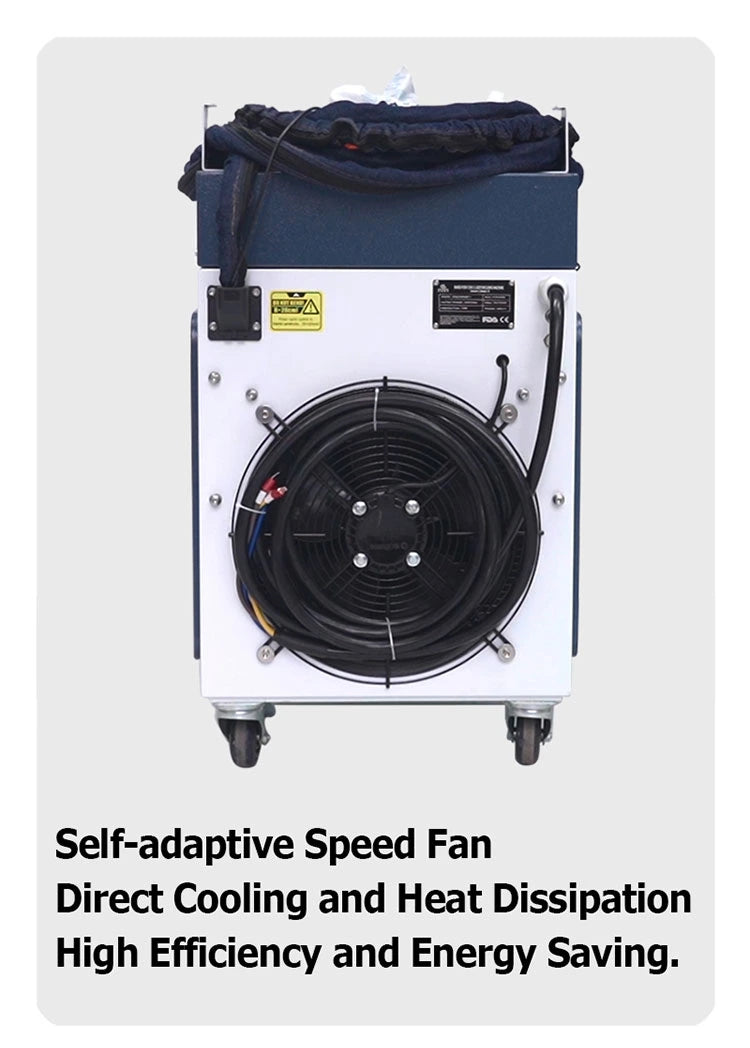

- Colling Model:Water Colling(deionized water, distilled water or pure water)

- Laser Cable Length:10m(can be customized to 15m or 20m)

- Model: Continious Laser Welding Machine

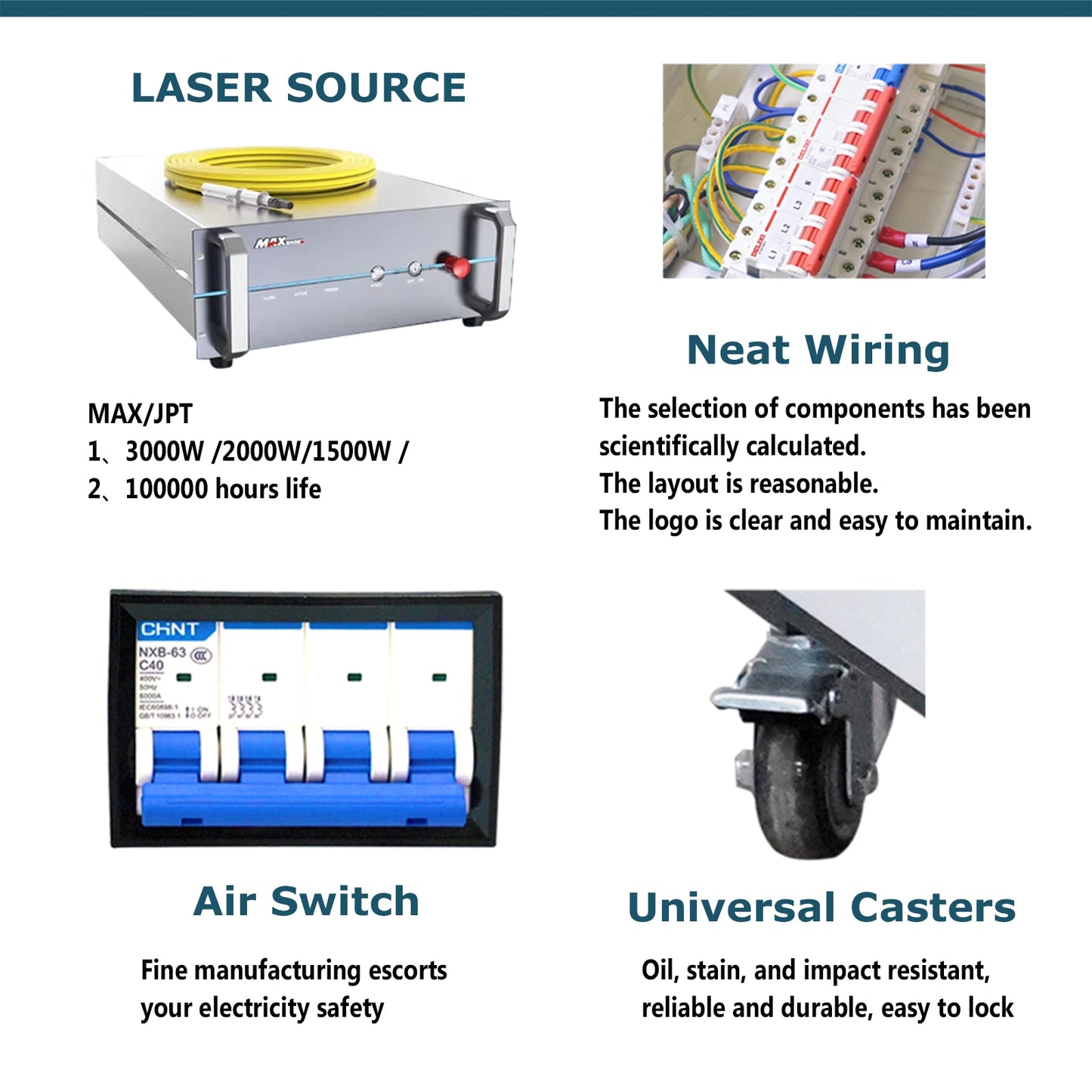

- Laser Source:MAX 2000W

- Laser Wavelength:1070±5nm

- Voltage:AC220V±10%

- Package Size:1120*560*1050mm

- Weight:113Kg

- Tank Capacity:16L(need to add water 14-15L)

Applications of Laser Welding Machines

- Laser welding machines are renowned for their high precision, efficiency, and low distortion, making them essential in advanced manufacturing. Key application areas include:

- Precision Electronics: Components like smartphone parts, lithium battery cells, and sensors benefit from minimal heat-affected zones.

- Automotive Manufacturing: Used for high-strength welding in power battery packs, motors, and vehicle bodies, with high automation capability.

- Medical Devices: Ensures clean, sealed welding of stainless steel and titanium alloys in endoscopes and surgical instruments.

- Hardware & Molds: Ideal for mold repair, saw blades, and kitchenware, offering high precision with minimal deformation.

- Aerospace: Welds high-temperature alloy components such as engine blades, meeting extreme-environment reliability requirements.

- Core Advantages: Non-contact processing, easy automation integration, and strong, aesthetically pleasing welds.

Service & Support

- Machine delivery with DDP shipping service, no extra cost.

- Machine comes with using video and we also have technical person at your service for the using guide.

- We provide 2 years warranty for whole machine, 1 years for laser source.

Share