What is a Fiber Laser Marking Machine? An Analysis of High-Efficiency Main Equipment in Industrial Marking

Share

What is a Fiber Laser Marking Machine? An Analysis of High-Efficiency Main Equipment in Industrial Marking

In the family of laser marking machines, fiber laser marking machines have become a "star equipment" in the current industrial marking field due to their excellent performance and wide applicability. With the continuous improvement of manufacturing industry's requirements for marking precision, efficiency, and anti-counterfeiting, the market demand for fiber laser marking machines is growing steadily. So, what exactly is a fiber laser marking machine? Why can it stand out among many laser marking equipment? This article will provide you with a comprehensive analysis.

A:Core Definition and Technical Principle of Fiber Laser Marking Machine

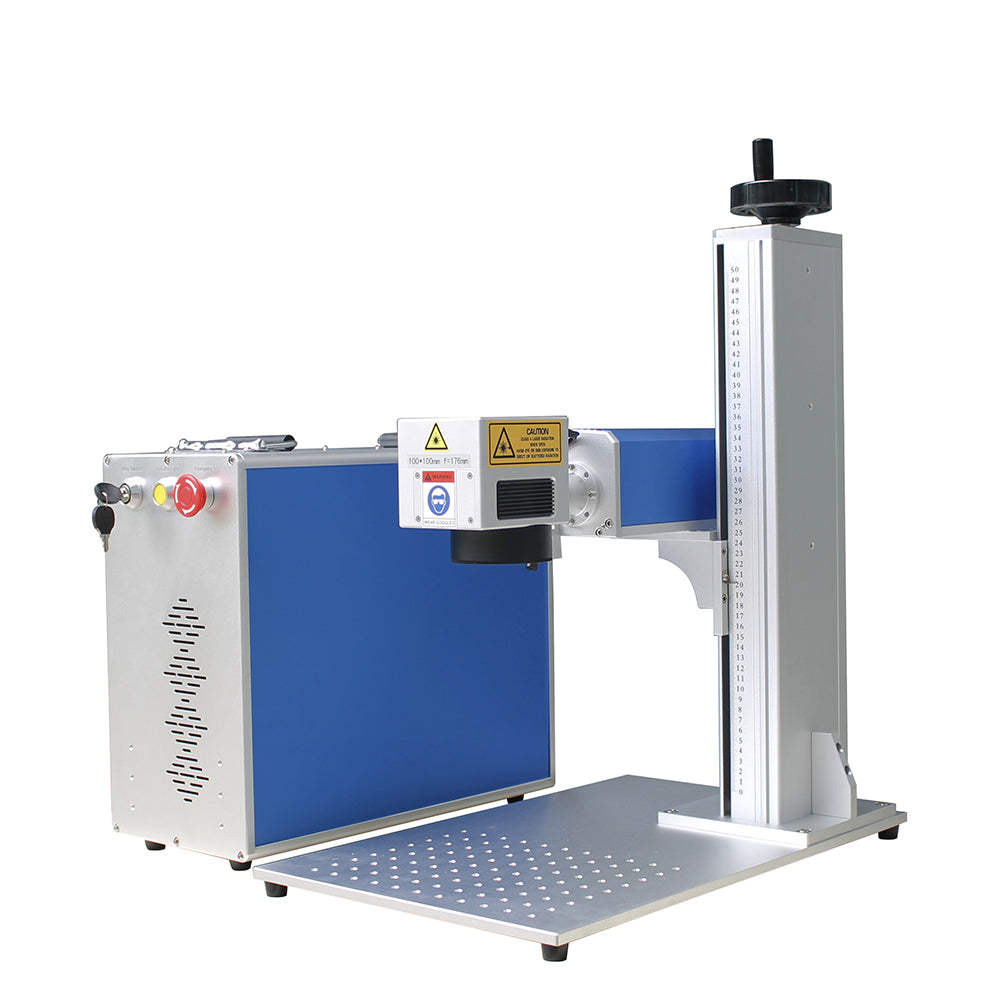

A fiber laser marking machine is a laser marking device with a fiber laser as the core light source, and it is an important branch of laser marking machines. It generates a high-energy-density laser beam through a fiber laser, which is focused by a galvanometer scanning system and acts on the surface of the workpiece, causing physical and chemical changes such as vaporization, melting, or discoloration on the surface layer of the material, thereby forming a permanent mark.

Its core technical advantage stems from the unique performance of the fiber laser: the fiber laser uses an optical fiber doped with rare earth elements as the gain medium, which has the characteristics of good beam quality, stable output power, and high conversion efficiency. After focusing, the diameter of the laser beam spot can be as small as the micrometer level, enabling high-precision marking of fine characters and complex patterns, which is also the core competitiveness of fiber laser marking machines different from other types of equipment.

B:Analysis of Core Advantages of Fiber Laser Marking Machine

Compared with traditional equipment such as CO₂ laser marking machines and semiconductor laser marking machines, fiber laser marking machines have significant advantages, which is the key reason for their rapid popularization in the industrial field:

a.Wide Range of Applicable Materials and Strong Compatibility

Fiber laser marking machines have natural advantages for metal materials and can perfectly mark various metal products such as stainless steel, aluminum alloy, copper, and titanium alloy; at the same time, they can also achieve clear marking on some non-metallic materials such as engineering plastics, ceramics, composite materials, and PCB boards, truly realizing the material adaptability of "one machine for multiple uses".

b.High Marking Efficiency and Fast Production Rhythm

The electro-optical conversion efficiency of fiber lasers can reach more than 30%, far exceeding that of traditional lasers. Under the same power, the marking speed is more than 50% higher than that of semiconductor laser marking machines. Equipped with a high-speed galvanometer scanning system, it can easily meet the high-efficiency marking needs of mass production and greatly improve the operation efficiency of the production line.

c.High Marking Precision and Excellent Anti-Counterfeiting Performance

Benefiting from the high-quality laser beam, the marking line width of the fiber laser marking machine can be as small as 0.01mm, which can clearly present tiny characters, QR codes, complex patterns, etc. The marked patterns are permanent, wear-resistant, corrosion-resistant, and not easy to be altered or counterfeited, providing a reliable guarantee for product traceability and anti-counterfeiting.

d. Low Operating Cost and Convenient Maintenance

The service life of fiber lasers is more than 100,000 hours, far exceeding that of traditional lasers, reducing the frequency of equipment replacement; there is no consumption of consumables during the operation of the equipment, only electric power support is needed, and the long-term use cost is significantly lower than traditional marking methods such as inkjet coding. At the same time, the fiber laser marking machine has a compact structure, and the modular design makes daily maintenance simpler, reducing the operation and maintenance pressure of enterprises.

C.Typical Application Scenarios of Fiber Laser Marking Machine

With comprehensive performance advantages, fiber laser marking machines have been widely used in many industrial fields and have become core equipment for product identification and traceability management:

a.Electronic Manufacturing Field

On electronic components such as mobile phone casings, chips, resistors and capacitors, and connectors, fiber laser marking machines can quickly mark information such as models, parameters, and QR codes, meeting the needs of the electronics industry for high-precision marking of tiny components and helping the construction of product quality traceability systems.

b.Automobile Parts Industry

For key identifiers such as automobile engine numbers, frame numbers, and component QR codes, fiber laser marking machines can achieve permanent marking on metal surfaces, which can withstand harsh environments such as high temperature and oil pollution, ensuring the traceability of the entire life cycle of automobiles and ensuring driving safety.

c.Medical Device Industry

On stainless steel surgical instruments and medical equipment casings, fiber laser marking machines can mark clear product numbers, sterilization dates, production batches, and other information. The marking process is free of chemical pollution, meeting the strict hygiene standards and quality requirements of the medical industry.

d.Hardware and Building Materials Field

From stainless steel pipes and valves to hardware tools, fiber laser marking machines can achieve high-adhesion marking, effectively resisting friction and corrosion in daily use, and improving the brand recognition and anti-counterfeiting ability of products.

D.Purchase Points and Industry Trends of Fiber Laser Marking Machine

When purchasing a fiber laser marking machine, enterprises need to focus on three core parameters: laser power, marking range, and software compatibility. Select the appropriate power according to the marking material and speed requirements (common 5W-100W), determine the workbench size according to the workpiece size, and at the same time ensure that the equipment is equipped with easy-to-use vector graphics processing software that supports the import of AutoCAD, CorelDRAW and other format files.

At present, fiber laser marking machines are developing towards the direction of "high power, high speed, and intelligence". With the popularization of automated production lines, more and more fiber laser marking machines equipped with visual positioning systems and robot linkage functions have emerged, which can realize unmanned automatic loading and unloading and precise alignment marking, further improving production efficiency. At the same time, the application of green energy-saving technologies has continuously reduced the energy consumption of equipment, which is more in line with the environmental protection needs of modern manufacturing industry.

As an efficient solution in the field of industrial marking, fiber laser marking machines, with their characteristics of high precision, high efficiency, and high reliability, have become important equipment to promote the upgrading of the manufacturing industry. Whether it is metal or some non-metallic materials, whether it is mass production or personalized customization, fiber laser marking machines can provide stable and reliable marking services, providing strong support for enterprises to improve product added value and strengthen quality traceability. With the continuous iteration of technology, the application boundary of fiber laser marking machines will continue to expand, creating value for more industries.