Your cart is currently empty!

What Is a Fiber Laser Marking Machine and Why Is It Essential for Modern Manufacturing?

·

Understanding Fiber Laser Marking Technology

A fiber laser marking machine is an advanced industrial tool used to create permanent, high-contrast markings on metal and selected plastic materials. By using a fiber laser source, this machine delivers a concentrated laser beam that interacts with the material surface to produce precise and durable marks.

Due to its stability, efficiency, and long service life, fiber laser marking technology has become a standard solution in modern manufacturing environments.

Advantages of Fiber Laser Marking Machines

High Stability and Consistent Performance

Fiber laser sources are known for their excellent beam quality and long-term stability, ensuring consistent marking results even during continuous operation.

Permanent and Wear-Resistant Marking

Laser marking does not fade, peel, or wear off, making it ideal for parts that require long-term identification and traceability.

Low Operating Cost

Unlike traditional marking methods, fiber laser marking machines require no consumables such as ink or chemicals, significantly reducing ongoing expenses.

Flexible Integration

Fiber laser marking machines can be easily integrated into production lines or used as standalone workstations.

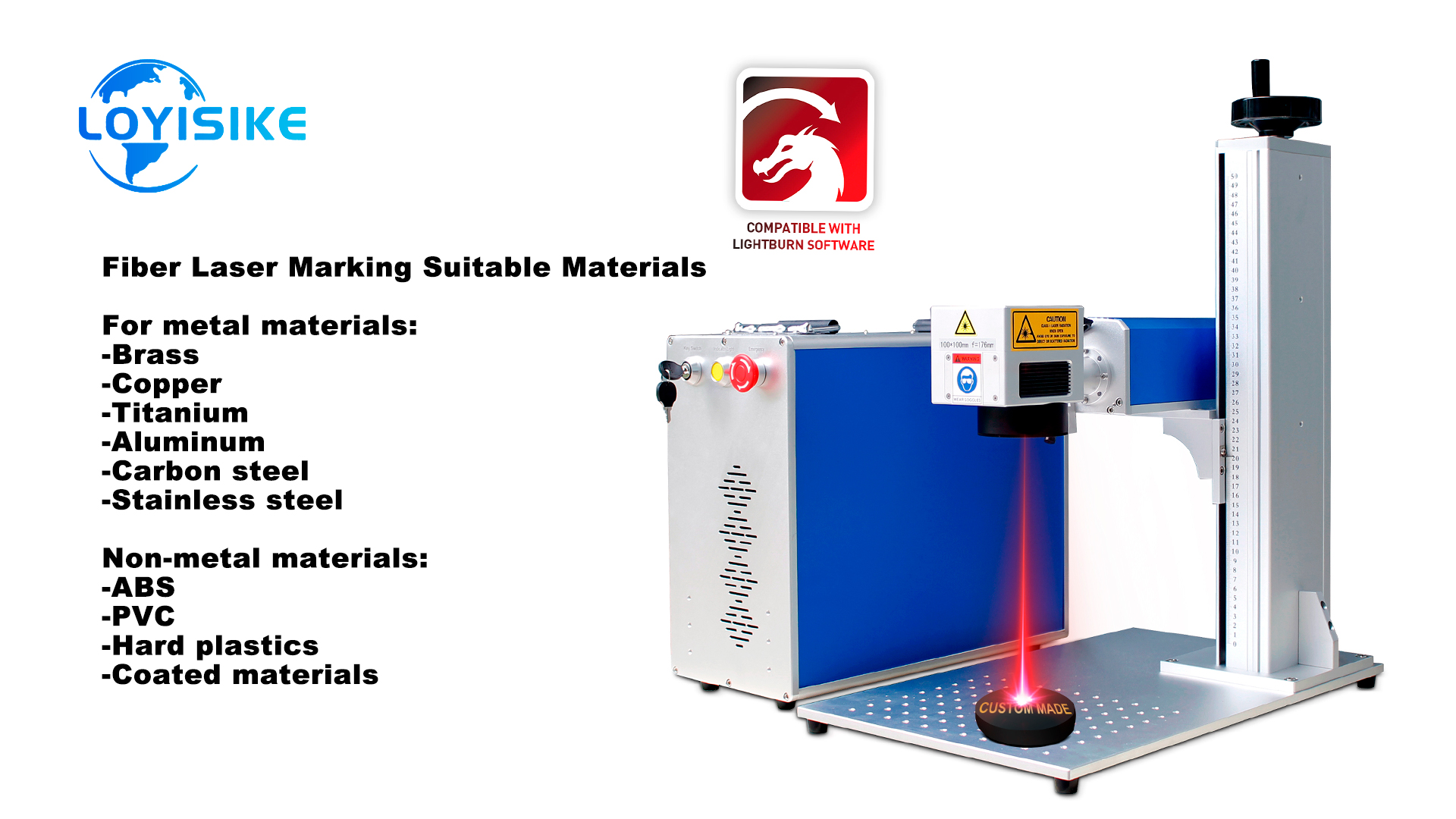

Typical Materials for Fiber Laser Marking

Fiber laser marking machines are optimized for metal materials, including:

- Stainless steel

- Aluminum alloys

- Brass and copper

- Carbon steel

- Nickel and titanium

They can also mark certain engineering plastics and coated materials depending on the application.

Industrial Applications of Fiber Laser Marking Machines

Manufacturing and Metal Processing

Used for part numbers, logos, and functional markings on tools, molds, and mechanical components.

Electronics and Electrical Industry

Ideal for marking PCBs, connectors, switches, and electronic housings with clear and readable codes.

Medical and Healthcare Equipment

Fiber laser marking machines meet the strict requirements for permanent, non-contact marking on medical instruments.

Automotive and Aerospace

Used to mark engine components, metal plates, and safety-related parts with high durability.

Fiber Laser Marking Machine Power Options Explained

Choosing the correct laser power is essential:

- 20W–30W: Suitable for standard surface marking and high-speed applications

- 50W: Ideal for deeper engraving and higher contrast

- Higher power models: Designed for industrial deep engraving and heavy-duty marking

Selecting the right power ensures optimal marking quality and efficiency.

Comparison: Fiber Laser Marking vs. Traditional Engraving

Traditional mechanical engraving can cause material deformation and tool wear. In contrast, fiber laser marking is:

- Non-contact and stress-free

- Faster and more precise

- Cleaner and environmentally friendly

- Suitable for automation and mass production

These advantages make fiber laser marking the preferred choice for modern factories.

How to Maintain a Fiber Laser Marking Machine

Proper maintenance ensures long-term performance:

- Keep the lens and optical components clean

- Ensure stable power supply and proper grounding

- Maintain appropriate operating temperature

- Follow manufacturer guidelines for regular inspection

With minimal maintenance, fiber laser marking machines can operate reliably for years.

Choosing the Right Fiber Laser Marking Machine for Your Business

When purchasing a fiber laser marking machine, consider:

- Application requirements and material types

- Required marking depth and speed

- Working area and system configuration

- Software compatibility and ease of use

- Supplier experience and after-sales support

A professional supplier can help tailor the best solution for your production needs.

Final Thoughts

A fiber laser marking machine is a powerful and cost-effective solution for manufacturers seeking precision, durability, and efficiency. Whether for traceability, branding, or compliance, fiber laser marking technology plays a crucial role in modern industrial production.

Investing in the right fiber laser marking system will significantly enhance product quality and operational efficiency.

Leave a Reply