Your cart is currently empty!

15Y Expertise in Laser Systems

One-Stop Laser Solutions for Marking, Cleaning, Welding, Cutting.

15-Years in Laser System

Crystal Engraver

3D Crystal Gifts, Souvenirs, and Personalized Designs with Permanent Internal Engraving.

Laser Cleaner

Eco-Friendly, Non-Contact Laser Systems for Rust Removal, Paint Stripping, and Surface Cleaning.

Laser Engraver

Permanent Marking of Text, Logos, and Codes on Metal and Non-Metal Materials.

Laser Welder

Provide Strong, Precise, and Low-Deformation Welding for a Wide Range of Metal Materials.

Advantageous products

Laser Cleaning Machine

200W/300W/500W/800W/1500W/2000W/3000W Pulse/Continuous Fiber Laser Cleaning Machine Could Fast Removal Metal Rust, Oil Stains, Painting, Oxidation Layer, Coating.

Advantageous products

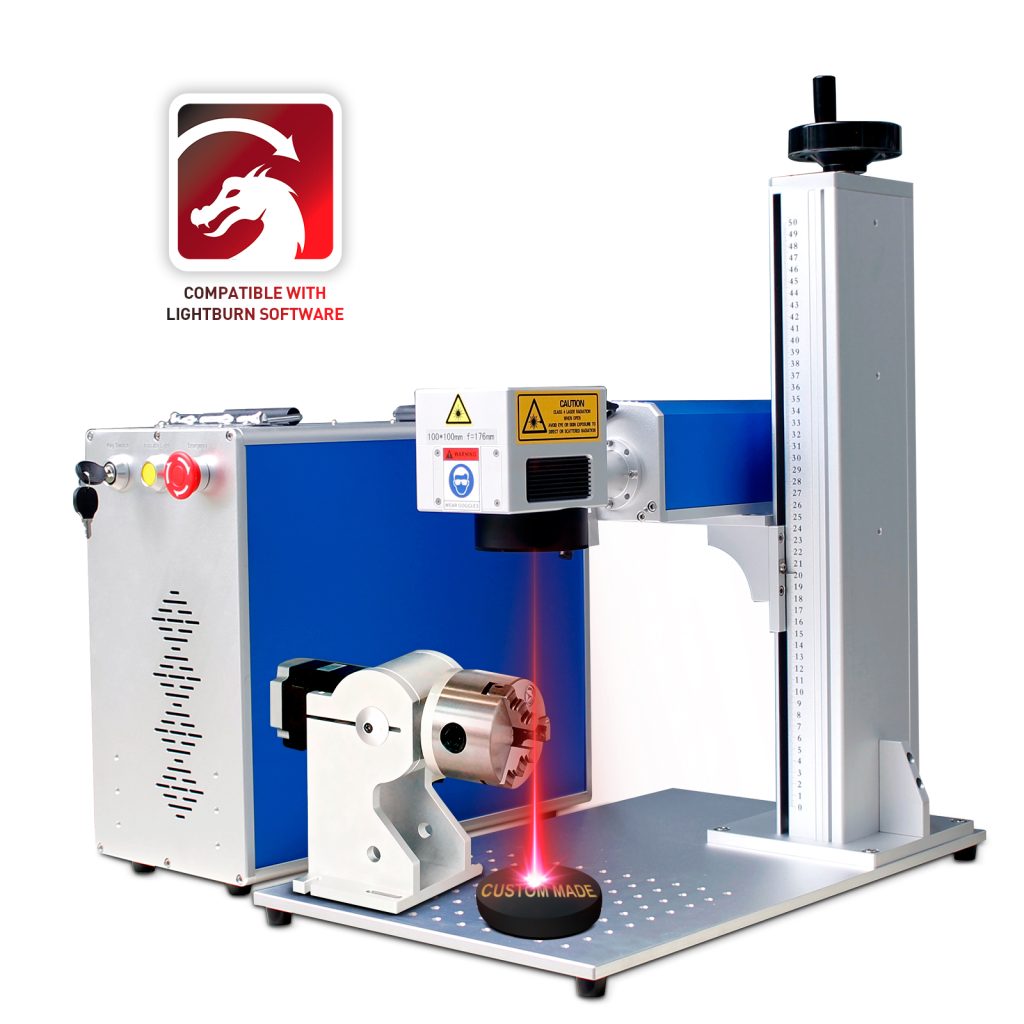

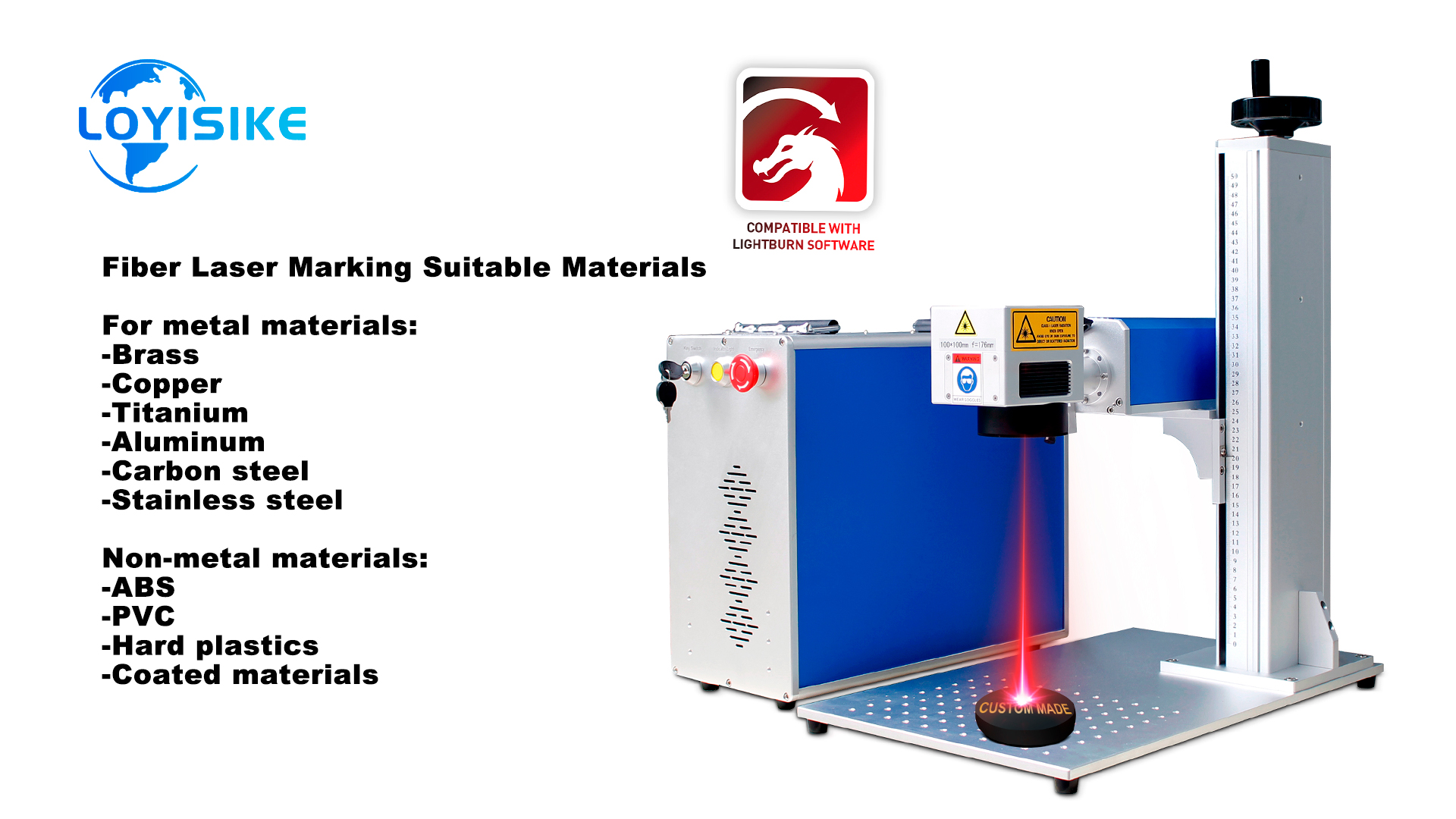

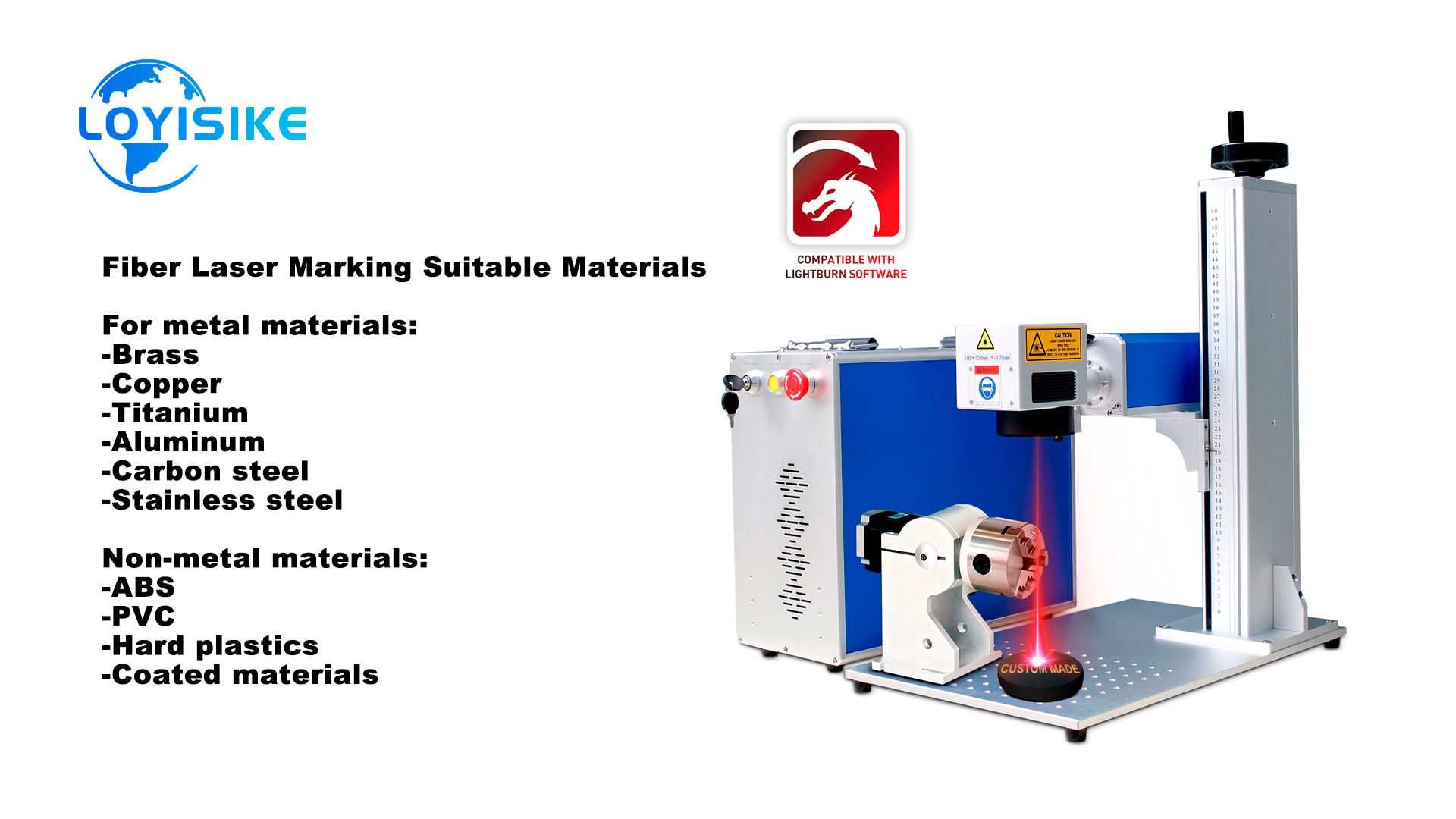

Laser Engraving Machine

Permanent marking of text, logos, and codes on metal and non-metal materials with high precision, consistency, and durability.

aBOUT US

luoyang shike Industrial Technology Co., Ltd.

Leading Intelligent Laser Equipment and Intelligent Manufacturing Solution Provider (Professional Laser Manufacturer | All Products CE/FDA/ISO9001 Certified).

LOYISIKE

15Y EXPERTIES IN LASER SYETEMS

- CE/FDA CETIFICATION

- JPT/MAX BRAND COOPERATED

- OEM/ODM SERVICE

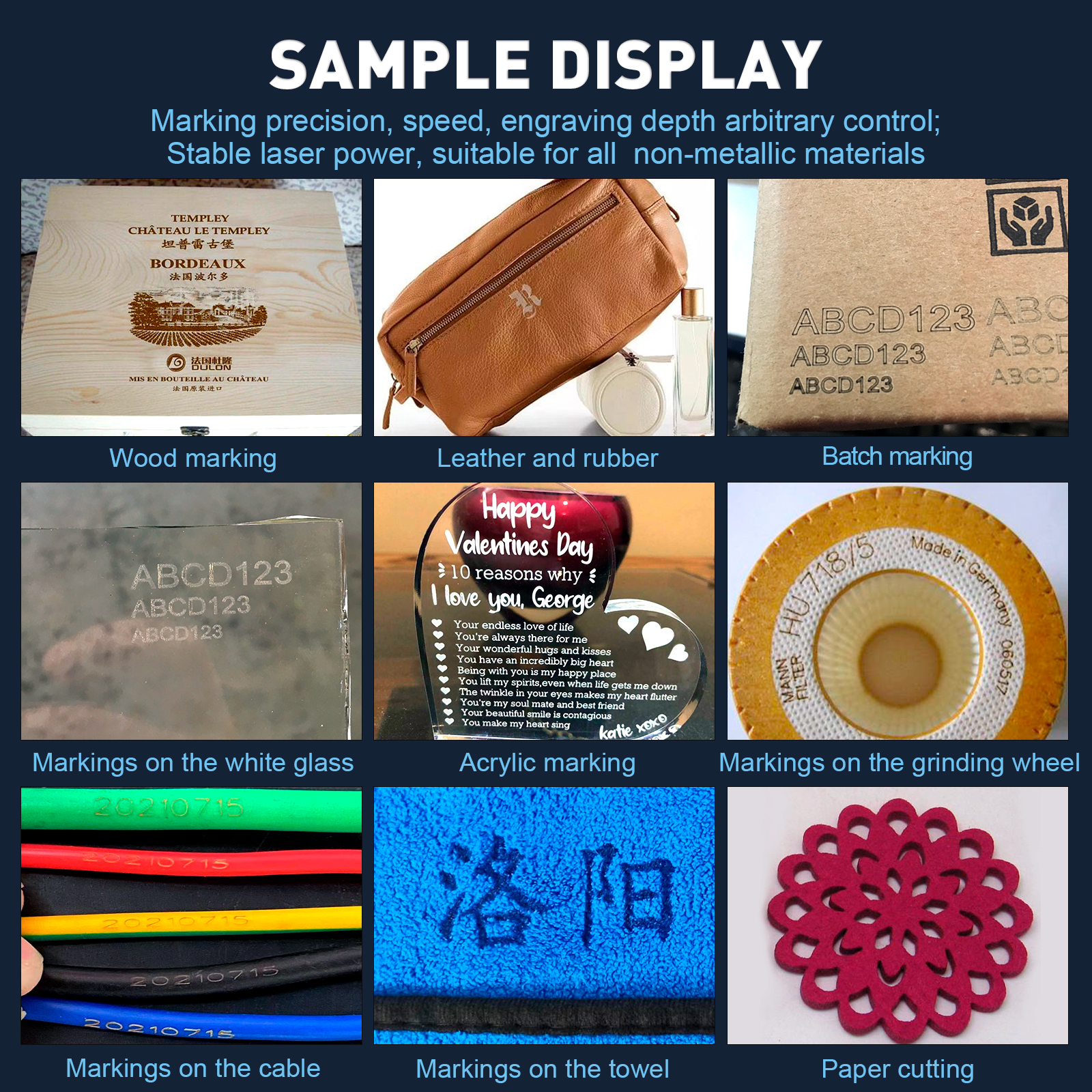

Sample Display

Explore real marking, cutting, welding, and cleaning results produced by our laser machines across various materials and industries.

Commendation

Customer Reviews

Trusted by manufacturers, workshops, and distributors worldwide. Hear real feedback from customers who use our laser machines in their daily production.

“This machine worked even better than expected! I was skeptical at first about laser cleaning, but my wonderful sales agent, Jenny, helped me throughout the process. Jenny was honest and informative about the product. This company also made shipping a much easier experience than I had with other suppliers from China. I hope to purchase from them again.”

Jacob Smith

“I waited a few week to give the right review. Delivery: Fast Quality: Very Good Product Description: Accurate Overall satisfaction is very good. Now I am using it for a couple of weeks. So fat the machine is excellent. MOPA colors are nice and persistent. Machine is well built and accurate. I am happy with my purchase.”

Michael Johnson

“I ordered a 2000W laser for cleaning metal, wood, & other materials. The price was reasonable, & manufacture & delivery timelines were very good. The machine works as promised, is well made, & easy to use. We have had no problems thus far. Customer service is competent. Overall we are pleased w/ the laser & expect to use it for many years.”

Joe Moore

faq

Frequently Asked Questions

Find quick answers to common questions about laser machine selection, applications, operation, and support.

How do I choose the right laser machine for my application?

Choosing the right laser machine depends on the material, application (marking, cutting, cleaning, or welding), required precision, working area, and production volume. By sharing your application details, our technical team can recommend the most suitable laser solution.

Are laser machines difficult to operate?

No. Our laser machines are designed for easy operation, featuring intuitive software interfaces and preset parameters. Even first-time users can get started quickly with basic training. We also provide user manuals, video guides, and remote technical support.

Are laser machines safe to use?

Yes. Our machines comply with international safety standards and are equipped with multiple safety features such as emergency stop buttons, protective enclosures, interlock systems, and alarm functions. Proper operation and protective equipment ensure a safe working environment.

What materials can laser machines process?

Laser machines can process a wide range of materials, including stainless steel, carbon steel, aluminum, copper, plastics, glass, ceramics, rubber, and certain composite materials. Material compatibility depends on the laser type, power level, and system configuration.

What is the maintenance cost of a laser machine?

Laser machines generally have low maintenance costs compared to traditional processing equipment. Routine maintenance mainly includes cleaning optical components, checking the cooling system, and regular inspections to ensure stable performance.

Do you provide after-sales service and technical support?

Yes. We offer comprehensive after-sales support, including installation guidance, operator training, remote technical assistance, spare parts supply, and long-term technical consultation throughout the machine’s service life.

News & Blog

-

What Is a Fiber Laser Marking Machine and Why Is It Essential for Modern Manufacturing?

Fiber laser marking machine Fiber laser marking system Industrial laser marking machine Metal laser marking equipment Fiber laser engraving machine

-

Fiber Laser Marking Machine: Features, Applications, and Buying Guide

Fiber laser marking machine Laser marking machine for metal Industrial fiber laser marker Metal laser engraving machine High precision laser marking

-

Laser Cleaning Machine Power Comparison: 300W vs 2000W

Understand the differences between a 300W and a 2000W fiber laser cleaner — what each power level is best for, pros & cons, cost…