Your cart is currently empty!

Fiber Laser Marking Machine: Features, Applications, and Buying Guide

·

A fiber laser marking machine is a highly efficient and precise solution for permanent marking on metal and selected non-metal materials. Thanks to its advanced fiber laser source, this technology is widely used in manufacturing, electronics, automotive, medical, and industrial production lines.

Compared with traditional marking methods, fiber laser marking offers high speed, long lifespan, low maintenance, and excellent marking quality, making it one of the most popular laser marking solutions worldwide.

How Does a Fiber Laser Marking Machine Work?

A fiber laser marking machine uses a fiber laser generator to produce a high-energy laser beam. The laser is guided through optical fibers and focused onto the material surface by a high-precision galvanometer scanning system.

The laser interacts with the material surface through oxidation, engraving, annealing, or color marking, creating permanent marks such as:

- Text and serial numbers

- Logos and graphics

- Barcodes and QR codes

- Date codes and batch numbers

The marking is non-contact, ensuring no mechanical stress or material deformation.

Key Features of Fiber Laser Marking Machines

1. High Precision and Clarity

Fiber laser marking machines provide extremely fine marking results, even for micro text and complex patterns. Ideal for high-accuracy industrial applications.

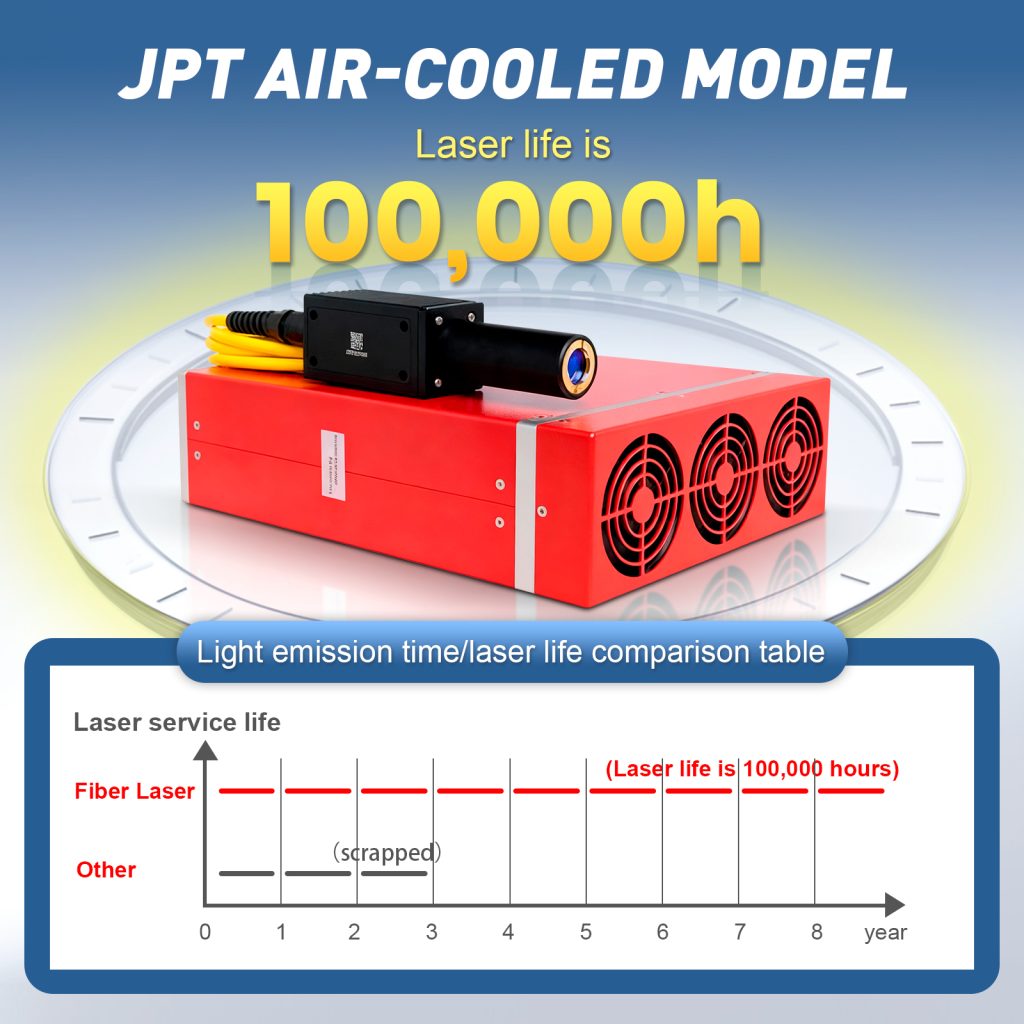

2. Long Service Life

The fiber laser source typically offers a lifespan of up to 100,000 hours, significantly reducing long-term operating costs.

3. Fast Marking Speed

With high-frequency laser output and fast scanning systems, fiber laser markers ensure high productivity and efficiency.

4. Low Maintenance Cost

No consumables, no ink, and minimal maintenance requirements make fiber laser machines cost-effective.

5. Environmentally Friendly

The marking process is clean, pollution-free, and compliant with modern environmental standards.

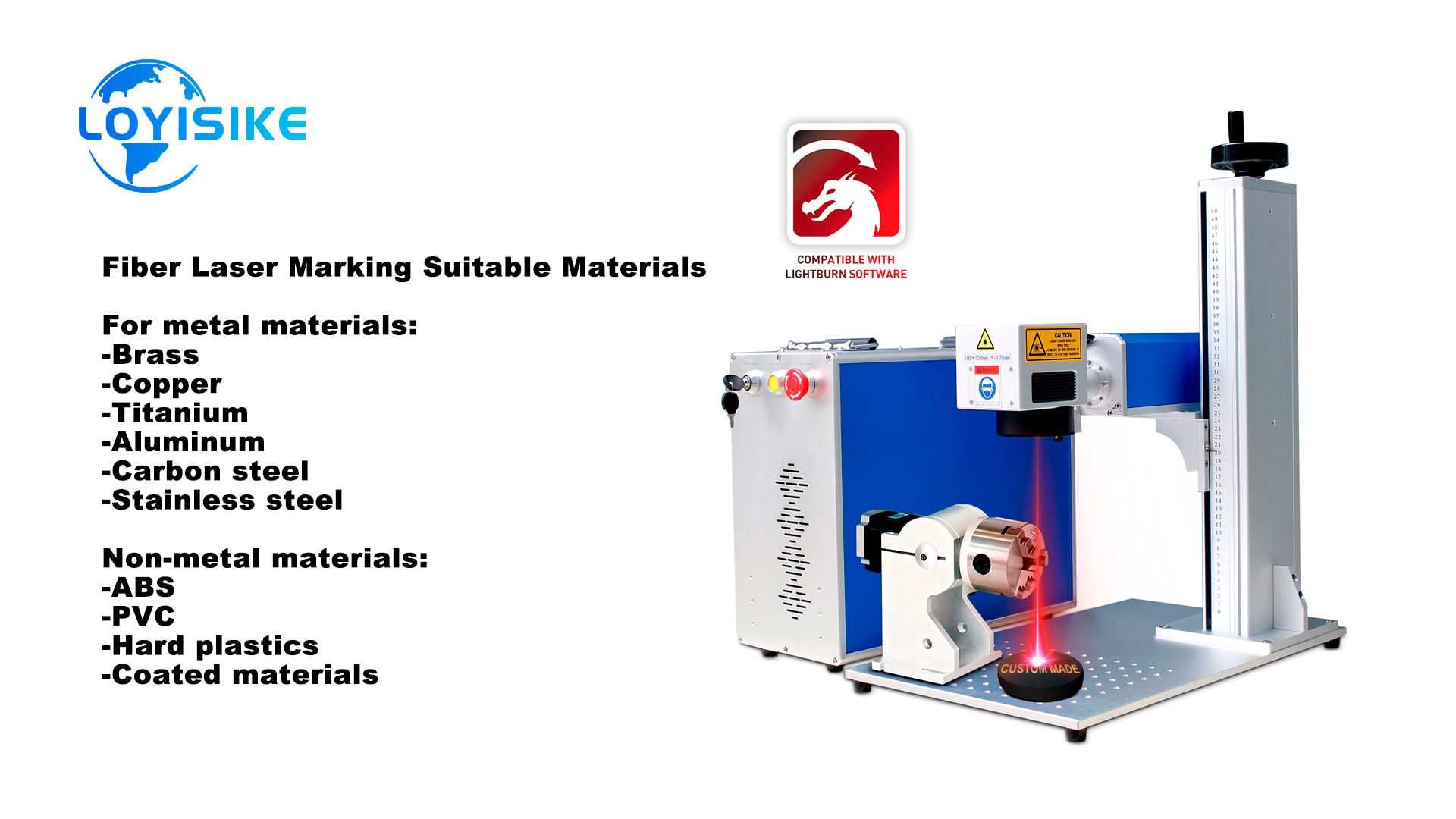

Materials Suitable for Fiber Laser Marking

Fiber laser marking machines are mainly designed for metal materials, including:

- Stainless steel

- Aluminum

- Brass

- Copper

- Carbon steel

- Titanium

They can also mark some non-metal materials, such as:

- Hard plastics

- ABS

- PVC

- Coated materials

Common Applications of Fiber Laser Marking Machines

Fiber laser marking machines are widely used across multiple industries:

- Automotive industry: engine parts, VIN codes, metal components

- Electronics: circuit boards, connectors, IC chips

- Medical devices: surgical tools, implants, medical equipment

- Hardware tools: tools, molds, bearings

- Jewelry and crafts: fine engraving and decorative marking

Their permanent and wear-resistant marking ensures traceability and brand recognition.

| Technology | Advantages | Limitations |

|---|---|---|

| Fiber Laser Marking | High precision, long life, low maintenance | Mainly for metals |

| CO₂ Laser Marking | Good for wood, acrylic, glass | Not ideal for metals |

| UV Laser Marking | Ultra-fine marking, cold process | Higher cost |

| Inkjet Marking | Low initial cost | Consumables, low durability |

How to Choose the Right Fiber Laser Marking Machine

When selecting a fiber laser marking machine, consider the following factors:

- Laser Power: Common options include 20W, 30W, 50W, and higher for deep engraving

- Marking Area: Choose the appropriate lens for your working size

- Material Type: Confirm compatibility with your materials

- Application Needs: Color marking, deep engraving, or high-speed marking

- After-Sales Support: Reliable technical support and warranty are essential

Why Choose a Professional Fiber Laser Marking Machine Supplier?

A reliable supplier ensures:

- Stable and high-quality laser sources

- Customized solutions for different industries

- Technical training and long-term support

- Fast delivery and global shipping

Choosing the right supplier helps you improve production efficiency and reduce operational risks.

Conclusion

A fiber laser marking machine is an ideal choice for manufacturers seeking high-quality, permanent, and efficient marking solutions. With its precision, durability, and low operating costs, it has become an essential tool in modern industrial production.

If you are looking for a reliable fiber laser marking solution, investing in a professional-grade fiber laser marking machine will bring long-term value to your business.

Leave a Reply